FEATURES

Drawing from its vast repository of customer feedback and technological data built up since its inception, YOTSUGI relentlessly improves product safety by employing its own test protocols and safety standards, and implements rigorous quality control and state-of-the-art manufacturing technologies at its own factories, in order to meet the needs of its customers in the best way possible.

Skilled sales staff cater to each customer’s unique needs

Optimal product development and customization plans are formulated and proposed based on customer inputs.

At YOTSUGI, we put top priority on our process of consulting with each customer to thoroughly understand their unique requirements, and then propose optimal solutions to address them. Since its foundation in 1934, the company has been building and implementing its product development and manufacturing capabilities to achieve superb know-how, work quality, and product safety, while utilizing customer inputs to continuously drive organizational growth. YOTSUGI formulates and delivers solutions that are optimized to the specific circumstances of each customer, rather than offering standard business pitches, products and services.

Technological prowess to deliver required solutions

Technical data and product development capabilities cultivated over the years since inception

In line with its corporate philosophy of protecting precious human lives and contributing to society through the attainment of safety, YOTSUGI’s core competency is its advanced technological capabilities and quality management structure that reliably ensure safety. The company leverages its vast repository of data on safety and security that has been accumulated since its inception, in order to fulfill its product design motto of “achieve reliability that matches the trust that society puts in the company.” All previous project records and technical data that have been compiled and organized by business category over the years are utilized to develop the next generation of products.

List of affiliated companies

These affiliated companies of YOTSUGI Co., Ltd. develop and manufacture products incorporating our proprietary technologies.

Yotsugi Techno Co., Ltd.

Yotsugi Techno Co., Ltd. manufactures electrically insulating gloves by using its latex processing technology. The raw material of the gloves is the latex (milky fluid) harvested from the rubber tree, to which certain additives are blended to formulate a rubber solution. Then, glove molds are immersed in the solution to produce YOTSUGI’s premium-quality natural rubber products. This latex manufacturing method does not typically use any solvents, thus reducing environmental impacts while achieving uniform thickness among products. The company strives to keep raising the quality of its products by using its foundational industry-leading latex processing technology.

- manufactured

goods - Protective electrical insulation gear incorporating latex processing technology, etc.

Yotsugi Chemical Co., Ltd.

Yotsugi Chemical Co., Ltd. mainly manufactures insulating tubular covers and bird repellent devices, leveraging its resin processing technology, which involves using many in-house injection and extrusion molding machines. The company also owns a wide range of testing devices (voltage tolerance testers, tensile testers, sunshine weather meters, brine-spray tracking-resistance testers, infrared spectrophotometers, 3-D printers, etc.) in order to meet the rigorous quality requirements of users, while implementing comprehensive and systematic quality control to ensure security and safety for customers.

- manufactured

goods - Molding and processing of resin products

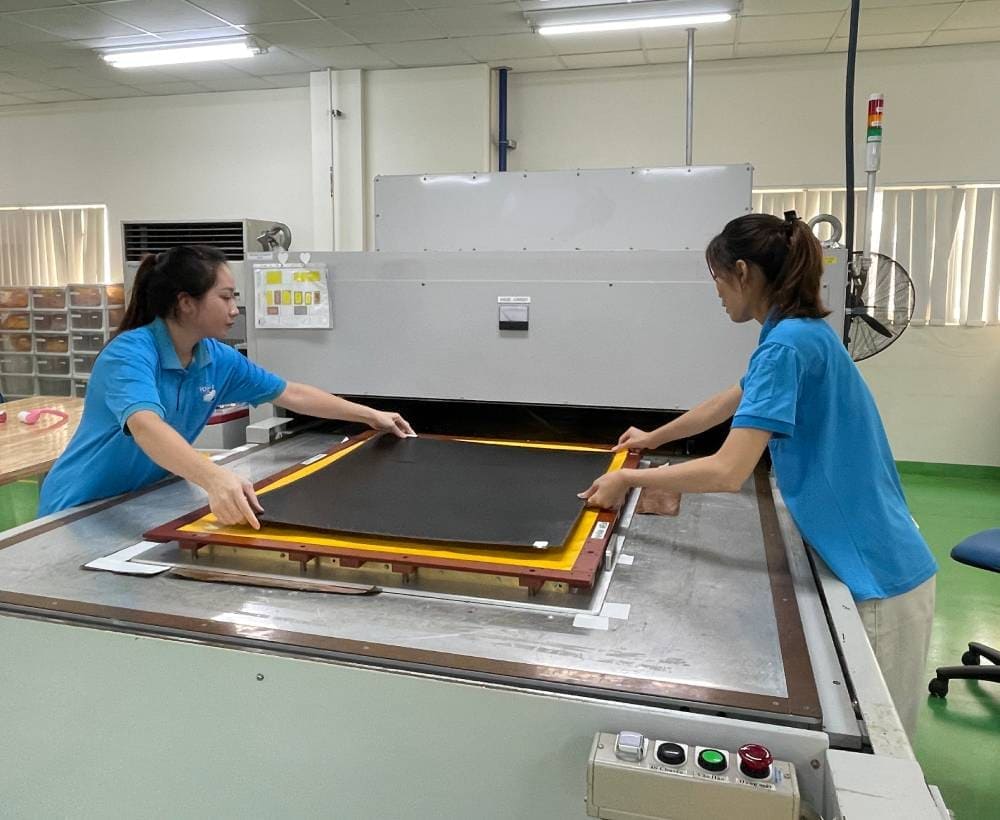

Yotsugi Vietnam Co., Ltd.

Yotsugi Vietnam Co., Ltd. manufactures a range of protective gear and equipment that provide electrical insulation, leveraging its resin processing technology. They are produced at the company’s factory in Hưng Yên province in Vietnam and are marketed under the YOTSUGI brand across Asia as well as in the U.S., Europe, the Near and Middle East, and other countries to meet their infrastructure demands.

- manufactured

goods - Electrical insulation gear and equipment for product protection

State-of-the-art facilities and equipment to remain an industry leader

Absolute quality requirements of products used in different industries

There is a constant need to stay abreast of the ever-changing times and environments and to keep delivering the best results while meeting diverse needs. The quality requirements of YOTSUGI’s products in different industries are strict, as the products are mission-critical in sustaining the social infrastructure that underpins our lives. To achieve this, stringent process management and robust product development, based on YOTSUGI’s proactive culture, are essential to maintain long-term trust. As its corporate philosophy is to protect precious human lives and contribute to society through the attainment of safety, YOTSUGI’s core competency depends on its advanced technological capabilities and quality management structure that reliably ensure safety. All safety products that YOTSUGI manufactures are required to meet stringent quality standards.

List of testing facilities and equipment used in product development

Withstand voltage tester

Verifies the insulation performance of products and materials by applying a voltage.

Withstand voltage tester

Verifies the insulation performance of gloves, sleeves, etc.

Weathering resistance tester (sunshine weather meter)

Verifies the deterioration tendency of products and materials through accelerated outdoor exposure.

Weathering resistance tester (metaling weather meter)

Verifies the deterioration tendency of products and materials through accelerated outdoor exposure.

Brine-spray tracking-resistance tester

Verifies the tracking resistance of products and materials through voltage application and brine spraying.

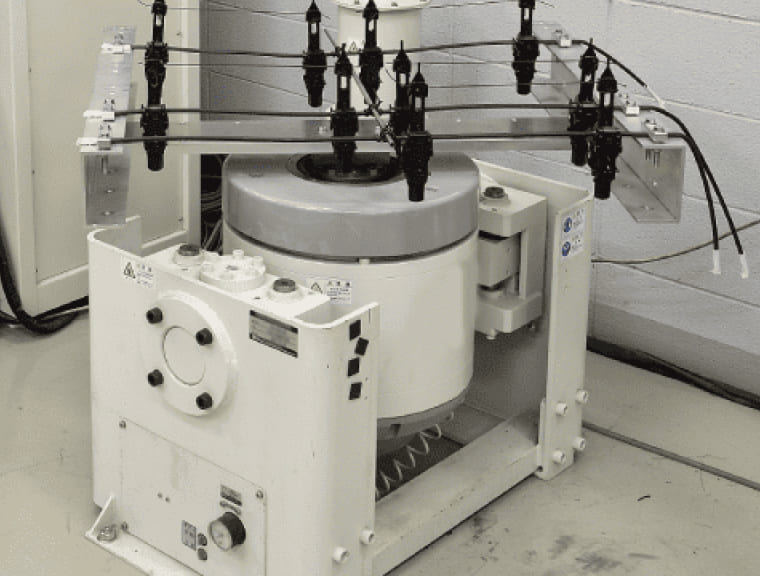

Vibration tester

Verifies the effects of vibration applied to products and materials under specific use conditions.

3D scanner

Scans the shapes of objects from various angles and converts the acquired data into usable digital format.

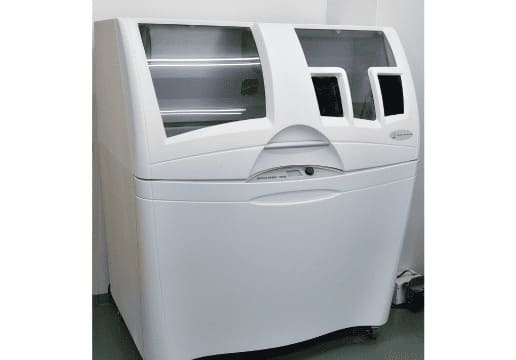

3D printer

Produces plaster sculptures based on 3-D data input.

Heat cycle tester

Examines the effects of large electrical currents on electrical cables and their connector materials, etc.

tensile testing machine

Measures the tensile strength, elongation, etc. of products and materials.

- TOP

- FEATURES